PROYECTOS

Anisopter crea y ejecuta proyectos orientados a ofrecer soluciones estructurales avanzadas para la industria.

Diseñamos y adaptamos nuestros métodos de optimización y sistemas de construcción a cada caso específico.

INVERSORES

Conoce a las empresas que colaboran con nosotros para impulsar nuestras tecnologías y generar un impacto positivo en la sociedad.

I+D

0

TECNOLOGÍAS

Nuestras soluciones para unir tubos en obra están protegidas por patentes y diseños industriales.

Sobre Nosotros

Anisopter se dedica al diseño y desarrollo de tecnologías avanzadas para la construcción eficiente de estructuras de celosía.

Noticias

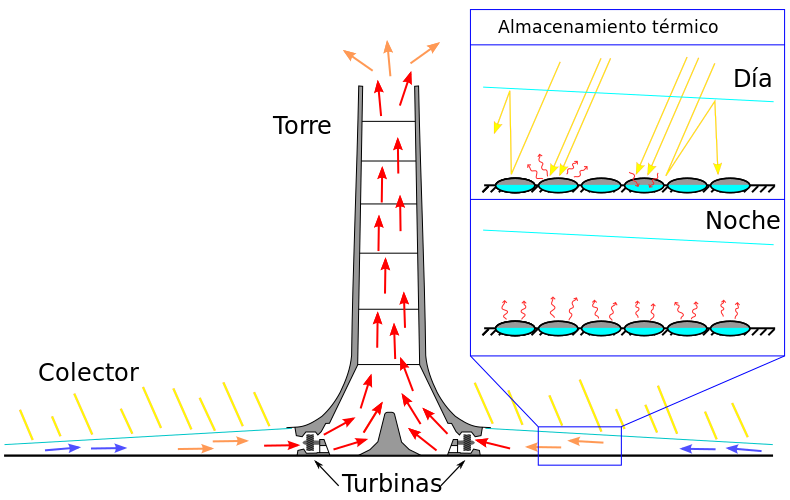

En Anisopter Insightful Research, seguimos avanzando con Red Eléctrica y […]

Our topology optimization study for OHTL (Overhead Transmission Lines) towers […]